CO2 Gas Plant

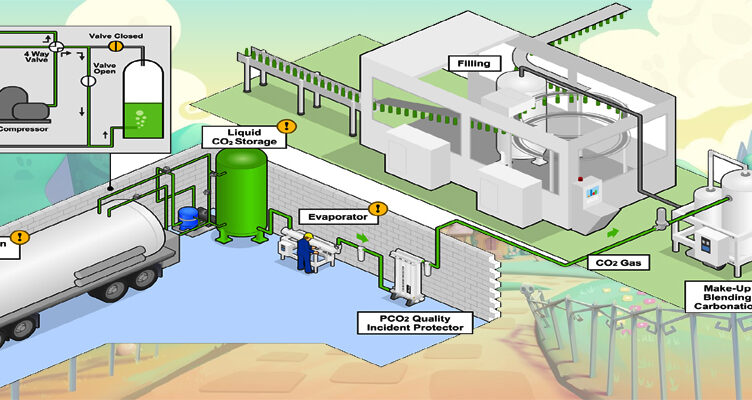

CO2 Recovery Plant takes CO2 Gas Plant from the fermentation process passes through a series of purification processes namely – a stainless steel CO2 foam trap to separate the gas, A deodorizer . At the same time, CO2 with a very high degree of purity is indispensable for the production process in a modern brewery. With our CO2 recovery plants we offer systems which meet all requirements of efficient carbon dioxide treatment: maximum purity with lowest O2 content and maximum yield.

CO2 Gas Manufacturers

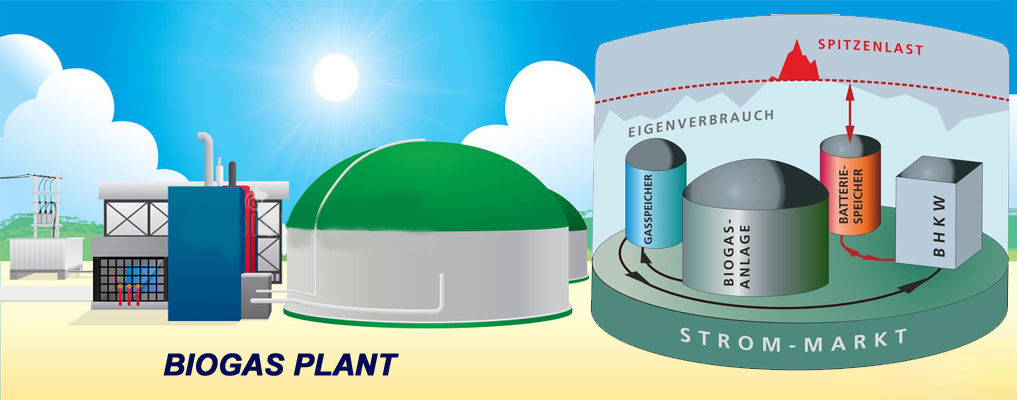

One solution is to extract CO2 from off-gas streams that would otherwise be vented to the atmosphere. This is referred to as carbon capture. Once captured, the CO2 can be purified and liquefied, and then supplied to a huge diversity of applications from horticulture and welding to cryogenic cleaning and carbonated drinks. Carbon recycling not only contributes to climate and environmental protection, it also has the added bonus of low supply costs and immediate availability of the gas. Alternatively, the Carbon Dioxide Plant can be sequestrated – in other words, stored underground – to mitigate the climate impact of industrial processes that rely on the combustion of fossil fuels.

CO2 Gas Production Plant

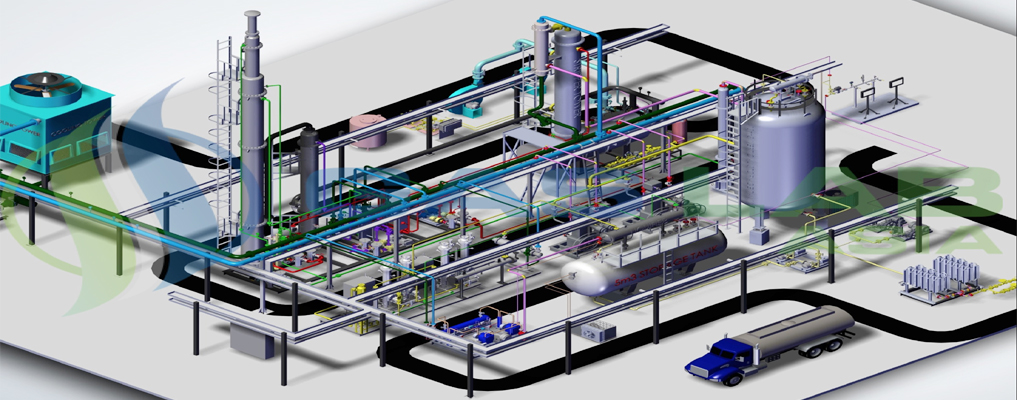

We are engaged in engineering, supplying and exporting a high quality assortment of Titanium Dioxide Calcification Plant. These offered plants are fabricated by using premium quality parts, material and advanced technology in compliance with international quality standards. Offered in capacity from 2 mt/hr up to 50 mt/hr, these plants are fired with pet coke, oil, gas and coal gas. This CO2 Gas Production is known for its high durability, reliable performance, easy operation, low maintenance and sturdiness. Our this Titanium Dioxide Calcification Plant can be availed from us at industry leading rates.

CO2 Gas Process

We are able to design a customized solution or offer a standard CO2 production plant to meet and exceed any customer requirements. Liquied CO2 Gas plants are based on burning of diesel, natural gas and/or kerosene. This complete & controlled fuel combustion process will generate flue gas with high CO2 content. The generated flue gas shall be washed & cooled first with Caustic Soda Solution in Scrubber / DCC (Direct Contact Cooler). At the next stage, the use of a cold, chemical absorbent “MEA” (Mono Ethanol Ammine) only recovers CO2 out of the flue gas which is at a later stage released from its absorbent by adding heat and stripping process.