Effluent Treatment Plant Process

Effluent is generated in many manufacturing industries like textile, pharmaceuticals and chemicals, tanneries etc. Contaminated water cannot be released without treatment as it contains toxic and non-toxic chemicals. Releasing it may cause contamination of the existing pure water and will affect the environment. As a result ETP’s are installed in most manufacturing industries.

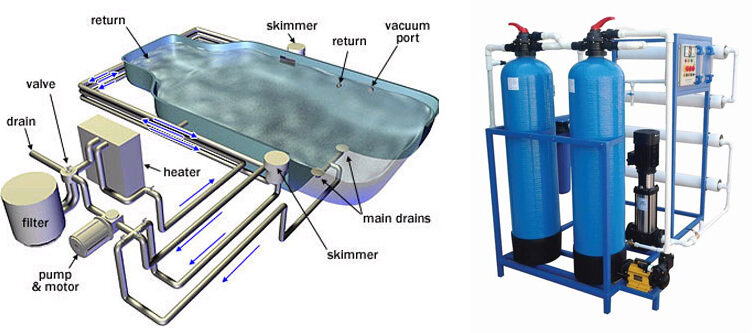

Effluent Treatment Plant Design

The Effluent treatment plants (ETP) are used for the removal of high amounts of organic compounds, debris, dirt, grit, pollution, toxic, non-toxic materials and polymers etc. from industrial effluent. The ETP plants use evaporation and drying methods and other auxiliary techniques such as centrifuging, filtration , incineration for chemical processing and Effluent Treatment Plant.

Effluent Treatment Plant Manufacturers

We Design, Manufacture, Supply, Erection and Commissioning Effluent Treatment Plant (ETP) on Turnkey basis for various types and natures of waste Waters, effluents which combines advanced physico-chemical treatment processes with tertiary polishing system for the removal of organic, inorganic, oil and grease, heavy metals & suspended solids.

Our methodology – We analyze the effluent samples for different Effluent Treatment Plant Suppliers parameters as per nature and compositions, carry out the treatability studies by using different methods checking techno-commercial Feasibility and then designed treatment schemes, processes accordingly to suit the purpose and need.

Effluent Treatment Plant PPT

We developed sewage technology and with matching equipments which can make up SBR’s many shortcoming in the base of Sequencing Batch Reactor Activated Sludge Process; which can widely used in all kinds of sewage treatment plant ‘s construction. The principle of integrated sewage treatment equipment is in a manner which organic combine Activated sludge microorganism method and biomem brane process, proceeding the sewage biochemical Effluent Treatment Plant PDF. In processing technology, a mass of microorganism grow in the fixed and floating biological carrier form into biomembrane, Impact flipping in the sewage with brume, proceeding update of bacterium and Biofilm ,using biological carrier in aeration , improve the contact efficiency of microorganism with the pollutant in the sewage. The whole treatment equipment generated take turn role of three types environment anaerobic-anoxia-aerobic ,enhance the purification ability of different kinds of microbial population to sewage, intensify the effect of remove the organism in sewage and N and P removal.